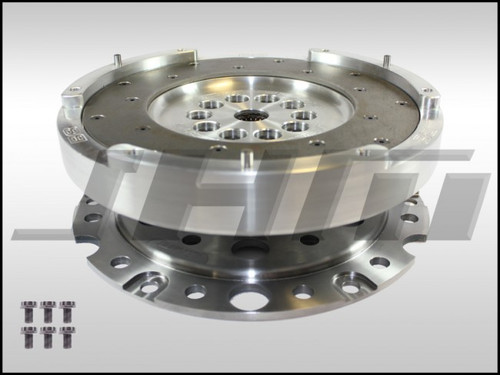

INTRODUCING THE JHM B8 S4-S5 3.0T LIGHTWEIGHT FLYWHEEL!!! After two years of research, development, prototyping, and testing we are finally ready to release our long awaited Lightweight Flywheel and Clutch Combo for the B8-S4 and B8-S5 with the 3.0T FSI! We began developing this kit in 2011 and have already installed it on several cars. We like to test all of our products for an extended period of time to verify the durability and longevity of the part before selling it publicly. In addition to working with our JHM Performance Clutch Kit , we have designed our JHM Lightweight Flywheel for the B8 S4-S5 so that it will work with an OEM stock clutch kit or ANY aftermarket clutch kit designed to work with the OEM B8 S4-S5 Flywheel.

Click to enlarge picture

Click to enlarge picture

Click to enlarge picture

Click to enlarge picture

Click to enlarge picture

Click to enlarge picture

CONCEPT AND DEVELOPMENT: The OEM Flywheel on the B8 S4 and S5 is a completely new design and a significant departure from Audi's previous flywheel designs. Instead of having the traditional single piece flywheel (i.e. the traditional "dual-mass flywheel") that just bolts to the back of the motor, the B8 S4-S5 flywheel is a two-piece, hourglass shaped, unit which allows Audi to position the motor further back in the chassis for better weight distribution. This is achieved by running a half-shaft through the narrow part of the hourglass shape in the flywheel. This major design change presented a new challenge for us. OEM B8-S5 FLYWHEEL, 2-PIECE: B8 S4-S5 4.2L V8 and 3.0T Flywheels are dimensionally the same with the only differences being small weight variations and different part numbers. Click to enlarge picture

CONCEPT AND DEVELOPMENT: The OEM Flywheel on the B8 S4 and S5 is a completely new design and a significant departure from Audi's previous flywheel designs. Instead of having the traditional single piece flywheel (i.e. the traditional "dual-mass flywheel") that just bolts to the back of the motor, the B8 S4-S5 flywheel is a two-piece, hourglass shaped, unit which allows Audi to position the motor further back in the chassis for better weight distribution. This is achieved by running a half-shaft through the narrow part of the hourglass shape in the flywheel. This major design change presented a new challenge for us. OEM B8-S5 FLYWHEEL, 2-PIECE: B8 S4-S5 4.2L V8 and 3.0T Flywheels are dimensionally the same with the only differences being small weight variations and different part numbers. Click to enlarge picture

Click to enlarge picture

Click to enlarge picture

Beginning in 2011, we tested out our Lightweight Flywheel concept by drilling out the rivets on the OEM unit and re-using the lower half of the OEM flywheel. We replaced the upper, cast-iron, dual-mass flywheel piece with a prototype version of a lightweight aluminum piece that we built in house. Once we were satisfied with the performance of our prototype, we went on making our own lower base out of machined steel, which can be seen above. This was done by completely re-engineering the overall unit for an optimal balance of strength and weight reduction. Click to enlarge picture

Beginning in 2011, we tested out our Lightweight Flywheel concept by drilling out the rivets on the OEM unit and re-using the lower half of the OEM flywheel. We replaced the upper, cast-iron, dual-mass flywheel piece with a prototype version of a lightweight aluminum piece that we built in house. Once we were satisfied with the performance of our prototype, we went on making our own lower base out of machined steel, which can be seen above. This was done by completely re-engineering the overall unit for an optimal balance of strength and weight reduction. Click to enlarge picture

WHY A LIGHTWEIGHT FLYWHEEL? Replacing the OEM, cast-iron, dual-mass flywheel with a single-mass, lightweight, aluminum piece reduces the overall weight of the rotating assembly of the motor. This frees up power in the motor and leads to increased throttle responsiveness. Changing the upper portion of the OEM flywheel to a single-mass unit also eliminates the potential for failure of the dual-mass unit. This is especially important on high-horsepower cars. Finally, the JHM Lightweight Flywheel offers the additional advantage of having a removable friction liner. If you end up replacing your clutch and pressure plate at a later date, you do not need to replace the entire flywheel OR worry about re-surfacing it (which - as of August 2013 - has yet to be done successfully for this large of a unit). Resurfacing would also not be cost effective due to tooling and fixture costs for such a tall, dual-mass flywheel. All you need to do is just replace the removable friction liner. JHM LIGHTWEIGHT FLYWHEEL SPECIFICATIONS: At JHM, we have weighed over a dozen OEM flywheels. We have seen a wide range of weight variances even on flywheels with the same part number! On average, the JHM Lightweight Flywheel weighs 8 to 10 lbs less compared to the OEM B8 3.0T Flywheel. When compared to the OEM 4.2L V8 Flywheel the JHM unit weighs 7 to 10 lbs less. PARTS INCLUDED:

WHY A LIGHTWEIGHT FLYWHEEL? Replacing the OEM, cast-iron, dual-mass flywheel with a single-mass, lightweight, aluminum piece reduces the overall weight of the rotating assembly of the motor. This frees up power in the motor and leads to increased throttle responsiveness. Changing the upper portion of the OEM flywheel to a single-mass unit also eliminates the potential for failure of the dual-mass unit. This is especially important on high-horsepower cars. Finally, the JHM Lightweight Flywheel offers the additional advantage of having a removable friction liner. If you end up replacing your clutch and pressure plate at a later date, you do not need to replace the entire flywheel OR worry about re-surfacing it (which - as of August 2013 - has yet to be done successfully for this large of a unit). Resurfacing would also not be cost effective due to tooling and fixture costs for such a tall, dual-mass flywheel. All you need to do is just replace the removable friction liner. JHM LIGHTWEIGHT FLYWHEEL SPECIFICATIONS: At JHM, we have weighed over a dozen OEM flywheels. We have seen a wide range of weight variances even on flywheels with the same part number! On average, the JHM Lightweight Flywheel weighs 8 to 10 lbs less compared to the OEM B8 3.0T Flywheel. When compared to the OEM 4.2L V8 Flywheel the JHM unit weighs 7 to 10 lbs less. PARTS INCLUDED:

- JHM Aluminum and Machined Steel 2-Piece Lightweight Flywheel Assembly

- 6x Flywheel to Flexplate Bolts FITMENT: All B8 S4-S5s with a 6-speed manual transmission and the 3.0T FSI motor. Our flywheel will work with any car that has a stock clutch and pressure plate OR an aftermarket clutch and pressure plate designed to work with a stock flywheel.

- B8 S4 with 3.0T FSI V6

- B8 S5 with 3.0T FSI V6 INSTALLATION INSTRUCTIONS AND TORQUE NOTES: These are NOTES ONLY are not a substitute for factory installation manuals or technical expertise. They are to be used a supplemental guideline only. We always recommend that an experienced technician perform ALL clutch and flywheel installations. For shops or individuals who have access to factory manuals but not factory tools, here are some tips and guidelines we have used to complete this job without the factory tools:

- The JHM Lightweight Flywheel installs in the same manner as the OEM Flywheel. Follow the OEM installation and torque procedures.

- Aligning the clutch disc, pressure plate, flywheel assembly: Install the throwout bearing/sleeve onto the transmission. For alignment of the clutch disc it is easiest to put the flywheel face-up, place and align the disc splines on center with the center bearing in the flywheel, put the pressure plate on top, visually check that the disc is still on center, and begin to tighten and torque the pressure plate. The pressure plate bolts need to be secured with red, high-strength Loctite. Make sure the pressure plate bolts are tightened in a star pattern at multiple torque intervals. This is to make sure that the pressure plate diaphragm or fingers are not distorted upon installation. Once the pressure plate is fully torqued to the flywheel with red Loctite to factory specifications (18 ft-lbs, in intervals), the clutch, pressure plate, and flywheel combination can now be slid onto the transmission as you would a torque converter on an Automatic Transmission. If the assembly will not slip on the transmission, this is most likely due to the fact that the disc is not on center. Remove the pressure plate and attempt to re-align the disc. **NOTE: We have successfully aligned the assembly by following the above procedure. It is not that difficult to "eyeball" the alignment.

- Once the clutch and flywheel combo are installed in the transmission, the half-shaft can be re-installed (this prevents the clutch and flywheel from falling out of the transmission while attempting re-installation). Install and bolt the transmission to the engine. Install the JHM supplied bolts for attaching the flywheel to the flexplate. Torque the flyweel to flexplate bolts to factory specifications. This is done in a similar fashion to torquing down a torque converter to a flexplate on an Automatic Transmission.

For shipping quotes: Please sign in or join then put the items you want in your shopping cart and proceed to checkout.

Click to enlarge picture

Click to enlarge picture

Click to enlarge picture

Click to enlarge picture

Click to enlarge picture

Click to enlarge picture

CONCEPT AND DEVELOPMENT: The OEM Flywheel on the B8 S4 and S5 is a completely new design and a significant departure from Audi's previous flywheel designs. Instead of having the traditional single piece flywheel (i.e. the traditional "dual-mass flywheel") that just bolts to the back of the motor, the B8 S4-S5 flywheel is a two-piece, hourglass shaped, unit which allows Audi to position the motor further back in the chassis for better weight distribution. This is achieved by running a half-shaft through the narrow part of the hourglass shape in the flywheel. This major design change presented a new challenge for us. OEM B8-S5 FLYWHEEL, 2-PIECE: B8 S4-S5 4.2L V8 and 3.0T Flywheels are dimensionally the same with the only differences being small weight variations and different part numbers. Click to enlarge picture

CONCEPT AND DEVELOPMENT: The OEM Flywheel on the B8 S4 and S5 is a completely new design and a significant departure from Audi's previous flywheel designs. Instead of having the traditional single piece flywheel (i.e. the traditional "dual-mass flywheel") that just bolts to the back of the motor, the B8 S4-S5 flywheel is a two-piece, hourglass shaped, unit which allows Audi to position the motor further back in the chassis for better weight distribution. This is achieved by running a half-shaft through the narrow part of the hourglass shape in the flywheel. This major design change presented a new challenge for us. OEM B8-S5 FLYWHEEL, 2-PIECE: B8 S4-S5 4.2L V8 and 3.0T Flywheels are dimensionally the same with the only differences being small weight variations and different part numbers. Click to enlarge picture  Click to enlarge picture

Click to enlarge picture  Beginning in 2011, we tested out our Lightweight Flywheel concept by drilling out the rivets on the OEM unit and re-using the lower half of the OEM flywheel. We replaced the upper, cast-iron, dual-mass flywheel piece with a prototype version of a lightweight aluminum piece that we built in house. Once we were satisfied with the performance of our prototype, we went on making our own lower base out of machined steel, which can be seen above. This was done by completely re-engineering the overall unit for an optimal balance of strength and weight reduction. Click to enlarge picture

Beginning in 2011, we tested out our Lightweight Flywheel concept by drilling out the rivets on the OEM unit and re-using the lower half of the OEM flywheel. We replaced the upper, cast-iron, dual-mass flywheel piece with a prototype version of a lightweight aluminum piece that we built in house. Once we were satisfied with the performance of our prototype, we went on making our own lower base out of machined steel, which can be seen above. This was done by completely re-engineering the overall unit for an optimal balance of strength and weight reduction. Click to enlarge picture  WHY A LIGHTWEIGHT FLYWHEEL? Replacing the OEM, cast-iron, dual-mass flywheel with a single-mass, lightweight, aluminum piece reduces the overall weight of the rotating assembly of the motor. This frees up power in the motor and leads to increased throttle responsiveness. Changing the upper portion of the OEM flywheel to a single-mass unit also eliminates the potential for failure of the dual-mass unit. This is especially important on high-horsepower cars. Finally, the JHM Lightweight Flywheel offers the additional advantage of having a removable friction liner. If you end up replacing your clutch and pressure plate at a later date, you do not need to replace the entire flywheel OR worry about re-surfacing it (which - as of August 2013 - has yet to be done successfully for this large of a unit). Resurfacing would also not be cost effective due to tooling and fixture costs for such a tall, dual-mass flywheel. All you need to do is just replace the removable friction liner. JHM LIGHTWEIGHT FLYWHEEL SPECIFICATIONS: At JHM, we have weighed over a dozen OEM flywheels. We have seen a wide range of weight variances even on flywheels with the same part number! On average, the JHM Lightweight Flywheel weighs 8 to 10 lbs less compared to the OEM B8 3.0T Flywheel. When compared to the OEM 4.2L V8 Flywheel the JHM unit weighs 7 to 10 lbs less. PARTS INCLUDED:

WHY A LIGHTWEIGHT FLYWHEEL? Replacing the OEM, cast-iron, dual-mass flywheel with a single-mass, lightweight, aluminum piece reduces the overall weight of the rotating assembly of the motor. This frees up power in the motor and leads to increased throttle responsiveness. Changing the upper portion of the OEM flywheel to a single-mass unit also eliminates the potential for failure of the dual-mass unit. This is especially important on high-horsepower cars. Finally, the JHM Lightweight Flywheel offers the additional advantage of having a removable friction liner. If you end up replacing your clutch and pressure plate at a later date, you do not need to replace the entire flywheel OR worry about re-surfacing it (which - as of August 2013 - has yet to be done successfully for this large of a unit). Resurfacing would also not be cost effective due to tooling and fixture costs for such a tall, dual-mass flywheel. All you need to do is just replace the removable friction liner. JHM LIGHTWEIGHT FLYWHEEL SPECIFICATIONS: At JHM, we have weighed over a dozen OEM flywheels. We have seen a wide range of weight variances even on flywheels with the same part number! On average, the JHM Lightweight Flywheel weighs 8 to 10 lbs less compared to the OEM B8 3.0T Flywheel. When compared to the OEM 4.2L V8 Flywheel the JHM unit weighs 7 to 10 lbs less. PARTS INCLUDED: - JHM Aluminum and Machined Steel 2-Piece Lightweight Flywheel Assembly

- 6x Flywheel to Flexplate Bolts FITMENT: All B8 S4-S5s with a 6-speed manual transmission and the 3.0T FSI motor. Our flywheel will work with any car that has a stock clutch and pressure plate OR an aftermarket clutch and pressure plate designed to work with a stock flywheel.

- B8 S4 with 3.0T FSI V6

- B8 S5 with 3.0T FSI V6 INSTALLATION INSTRUCTIONS AND TORQUE NOTES: These are NOTES ONLY are not a substitute for factory installation manuals or technical expertise. They are to be used a supplemental guideline only. We always recommend that an experienced technician perform ALL clutch and flywheel installations. For shops or individuals who have access to factory manuals but not factory tools, here are some tips and guidelines we have used to complete this job without the factory tools:

- The JHM Lightweight Flywheel installs in the same manner as the OEM Flywheel. Follow the OEM installation and torque procedures.

- Aligning the clutch disc, pressure plate, flywheel assembly: Install the throwout bearing/sleeve onto the transmission. For alignment of the clutch disc it is easiest to put the flywheel face-up, place and align the disc splines on center with the center bearing in the flywheel, put the pressure plate on top, visually check that the disc is still on center, and begin to tighten and torque the pressure plate. The pressure plate bolts need to be secured with red, high-strength Loctite. Make sure the pressure plate bolts are tightened in a star pattern at multiple torque intervals. This is to make sure that the pressure plate diaphragm or fingers are not distorted upon installation. Once the pressure plate is fully torqued to the flywheel with red Loctite to factory specifications (18 ft-lbs, in intervals), the clutch, pressure plate, and flywheel combination can now be slid onto the transmission as you would a torque converter on an Automatic Transmission. If the assembly will not slip on the transmission, this is most likely due to the fact that the disc is not on center. Remove the pressure plate and attempt to re-align the disc. **NOTE: We have successfully aligned the assembly by following the above procedure. It is not that difficult to "eyeball" the alignment.

- Once the clutch and flywheel combo are installed in the transmission, the half-shaft can be re-installed (this prevents the clutch and flywheel from falling out of the transmission while attempting re-installation). Install and bolt the transmission to the engine. Install the JHM supplied bolts for attaching the flywheel to the flexplate. Torque the flyweel to flexplate bolts to factory specifications. This is done in a similar fashion to torquing down a torque converter to a flexplate on an Automatic Transmission.

For shipping quotes: Please sign in or join then put the items you want in your shopping cart and proceed to checkout.

This product fits the following vehicles:

| Make | Model | Chassis | Engine |

|---|---|---|---|

| Audi | S5 | B8-B8.5 (2008-2017) | 3.0t V6 24v SC |

| Audi | S4 | B8-B8.5 (2010-2016) | 3.0t V6 24v SC |