Overview

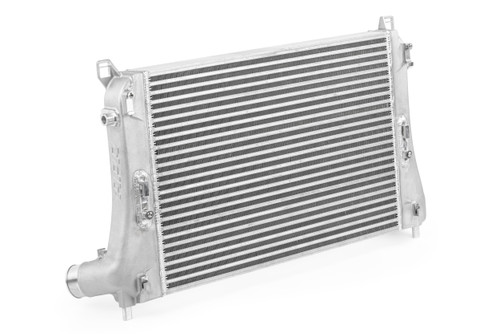

Features:

- Dramatically lowers intake air temp (IAT)

- -- Increases horsepower while minimizing power-robbing heat soak!

- -- Effectiveness tested to over 500 HP!

- -- 21 horsepower gain over the factory system!

- Massive core size

- -- Use of the OEM-location allows for a massive intercooler core.

- -- 24.25" x 16.25" x 1.16" - 457.1 in³ - OEM Tiguan

- -- 24.25" x 16.25" x 1.25" - 492.5 in³ - OEM MK7 GTI

- -- 24.25" x 16.25" x 1.37" - 529.8 in³ - OEM MK7 Golf R (Similar to Arteon)

- -- 24.00" x 16.25" x 2.25" - 877.5 in³ - APR

- Intercooler installed in the best location for this platform

- - Utilizes factory air dams for exceptional airflow across the core.

- - 100% compatible with the Adaptive Cruise Control (ACC) system.

- Highly effective core design

- -- Bar-and-plate core with staggered and louvered fins.

- -- Rigorous testing determined core style, fin density, and size.

- -- Low pressure drop + highly effective cooling = high performance!

- Smooth cast end tanks

- -- Engineered for low turbulence/restriction and maximum flow.

- -- Organically shaped to promote airflow across entire core.

- -- Pressure tested to prevent power robbing boost leaks.

- -- No hidden labor costs or permanent modifications

- No trimming, cutting, or other costly modification required.

- -- No modification to the Adaptive Cruise Control System required.

- -- Full directions and APR world-renowned customer support included.

- Designed by engineers with lasers

- -- With the best equipment and smartest engineers, it just works!

Fits: VW Arteon 2019+ / with 8 Speed AT

VW Tiguan 2018+ / with 8 Speed AT

Audi Q3 2019+ / with 8 Speed AT